ENOUGH IS ENOUGH: UNCOVERING THE REALITY OF “1-DAY POLYUREA” COATING SYSTEMS

The demand for concrete coating systems is on the rise. This has led to a surge of new companies entering this space, with many focusing on offering “1-day polyurea” or “1-day polyaspartic” solutions. The appeal lies in their speedy installation process which offers minimal interruptions for clients. To achieve this quick turnaround time, these contractors use fast-curing products like polyureas or polyaspartics, allowing them to complete an entire job within one day. However, speed doesn’t always equate to quality, as explained by GarageFloorCoating.com in their August 2020 article titled “Polyurea-Polyaspartic One-Day Systems: Do They Work“…and they’ve been applying concrete coatings since 1996.

What are 1-Day Polyurea or 1-Day Polyaspartic Coatings?

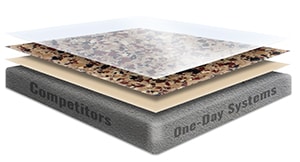

Contractors who offer one-day installations use liquid coatings known as “polyureas” or “polyaspartics”. In “1-day” concrete coating systems, these products are used as both the primer coat and top coat. Due to their rapid cure times, the primer coat and the clear top coat (with full-flake broadcast sandwiched between) can be installed within a single day! This is an attractive feature to the contractor as the one-product-fits-all approach saves the contractor both in product costs and labor costs. While polyurea-polyaspartics do possess impressive properties, including fast cure rates and extreme chemical and UV resistance, there are major problems with the “1-day” approach.

What distinguishes a Polyurea from a Polyaspartic?

A polyurea is a protective coating that, with its almost instant drying time (seconds), is a great coating for large surface area projects. It’s used in roofing, as a manhole and tunnel coating, and as a tank and truck bed liner. However, to install a “pure” polyurea correctly, specialized equipment like a portable reactor, is necessary (owing to the products extremely short curing rate). However, this quick-cure property can be a problem when coating concrete. Applicators need the cure rate to be slowed so the product can be applied with rollers or squeegees…not portable reactors!

So chemists have modified “pure” polyureas to create an aliphatic polyurea (or, as it is commonly called, a “polyaspartic”). An aliphatic polyurea (or polyaspartic) is modified to slow its cure rate down, rendering this coating more “user-friendly” (that is, friendly enough to be applied with a simple roller). So, a polyaspartic is essentially a chemically-modified, slowed-down version of a polyurea. Regardless whether the contractor sells you a “1 day polyurea” system or a “1-day polyaspartic” system, it’s fundamentally the same. Both use fast-cure coatings as the primer coat and the clear top coat.

So Why are “1-Day Systems” like Playing Russian Roulette?

Despite the fast curing rate of a polyurea (or polyaspartic, whatever your contractor calls it), they have a major downside. They’re not designed for direct application to concrete surfaces with high moisture content. This is because the moisture-vapor transmission (MVT) permeating through porous concrete can, over time, cause high hydrostatic pressures which delaminate (peel away) thinly applied coatings. Applying thicker coats would seem like an obvious solution, but due to the chemical properties of polyurea-polyaspartics, it’s impossible to do so (as the coating simply won’t cure effectively). So the wafer-thin layer of a polyurea-polyaspartic primer that 1-day contractors apply, isn’t capable of protecting your floor against high hydrostatic pressures! Applying these products direct-to-concrete is like playing Russian Roulette.

Proper Application Using an Epoxy Primer & Polyaspartic Topcoat

However, epoxies cure differently. When mixing an epoxy, the amount (its mass) determines the amount of exothermic heat generated…which determines the reaction time. The thicker the mass, the better an epoxy cures. This is why epoxies can be applied thickly and act as great primer coats (they’re called “high build” coatings). A quality, moisture-mitigating epoxy can prevent moisture infiltration and withstand much higher hydrostatic pressures than a wafer-thin polyurea-polyaspartic primer.

So (honest) contractors use a moisture-mitigating epoxy as the primer coat…and only use the polyaspartic as the clear topcoat. (But because an epoxy takes longer to cure, the installation process takes up to 2 days, not 1). “1-day” contractors know this and so: (a) try to discredit epoxy products, and (b) add warranty exclusions in their contracts for “moisture-related issues”. Very tricky! Given that moisture-related issues are the number one reason for coating system failures, the “warranty” really isn’t worth the paper it’s written on.

Honest contractors know that all coating types have their strengths and limitations…so they have all coating types – epoxies, polyurethanes and polyurea-polyaspartics – in their arsenal. While epoxies are great primer coats, they’re lousy topcoats (because they tend to amber and fade in the presence of UV light). Conversely, polyurea-polyaspartics are excellent topcoats, but a poor choice as primers, because they don’t offer protection against high hydrostatic pressures (and peel). So we use both…where they are the most effective!

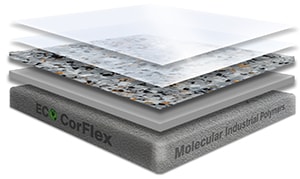

Our Systems are Different: They’re Industrial-Grade

We only provide industrial-grade flooring solutions. Our proprietary, moisture-mitigating,100%-solids epoxy is used as the primer coat in all our coating systems (we’ll never use a polyurea direct-to-concrete). We then broadcast our unique flake blends (and you can select from our beautiful mica-infused blends as well; something not offered by our competition). We’ll finish off your floor with not one, but two coats of our clear 100%-solids polyaspartic for real protection and resilience. The end result? A robust, industrial-grade, 35+ mil thick garage floor coating, impervious to any moisture-related conditions.

Looking for heavy-duty, full-flake garage floor coatings backed by a real warranty? Your search ends here! Contact GatorGuard of Columbus at (877) 324-2628 today for your free, no-obligation quote.